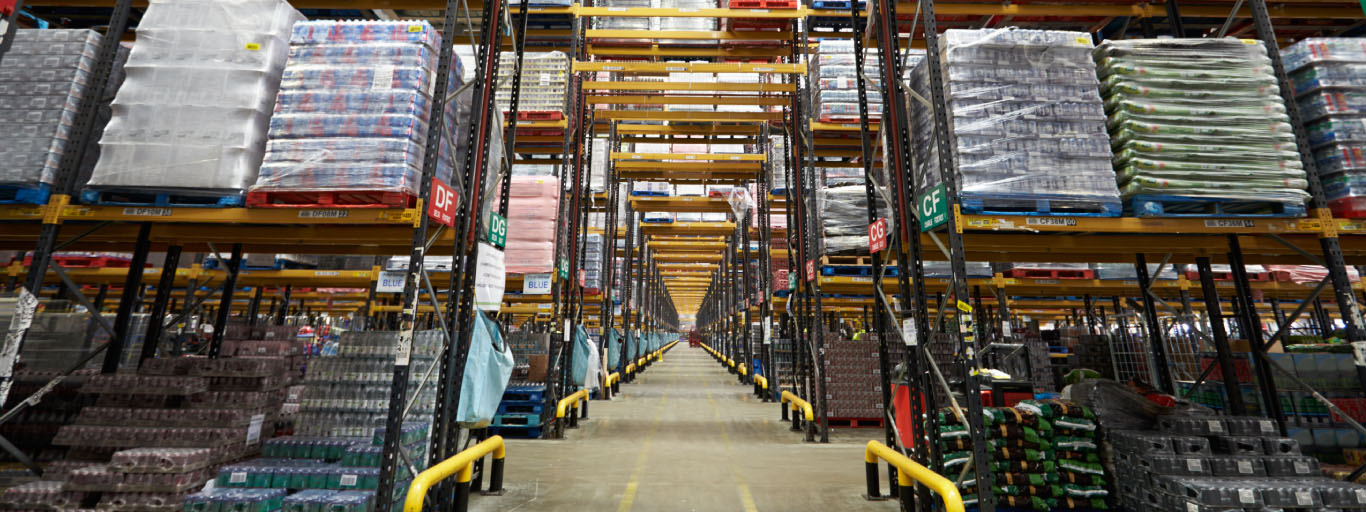

Warehouses can sometimes appear like a gigantic maze and treasure hunt, all rolled into one. As workers are constantly darting back and forth to pick orders in a warehouse setup, an inefficient system can drastically decrease the overall picking and delivery speeds. To ensure better productivity and to meet the demands of customers, the management team often gets tasked with the responsibility of setting up a system to compensate for loopholes that come in the way of efficiency. Directing and controlling the movement of goods, right from the assembly point requires careful attention. This is where ‘wave picking’ comes into play.

What is Wave Picking?

Wave picking is a type of picking method in which multiple orders are combined and scheduled to be picked at the most appropriatetime of the day. The basic premise behind wave picking is optimizing the process of picking orders that are scheduled for fulfilment. It involves the allocation of specific inventory or storage zone from where the employee can pick up during specific times throughout the day. The group of orders to be released is known as a wave. Wave picking can be used in both high and low volume operations. The orders are grouped and scheduled using the following considerations:

- Shipping schedules

- Shift changes and available workforce

- Replenishment cycles

- Carriers

- Product locations and commodity

- Priorities

Wave picking is believed to be the most efficient method since items get grouped already in their respective batches before being transported into their respective zone terminals. Since goods are sorted before they are waved away, tracking becomes easier, especially for counting purposes. Additionally, waiving facilitates the release of goods in high numbers for the purpose of supply. It leads to more efficient picking of orders.

How to Optimize a Wave Picking Strategy?

There are a few practices for creating a wave picking strategy implemented by the best warehouses in Pune and everywhere else. The first thing required is a robust and effective warehouse management system or WMS software platform. WMS helps evaluate the different variables impacting the number of orders, delivery times, labour schedules of pickers, pickup schedules of carriers, and location of each product.

The Delivery Commitment

Delivery commitment is one of the primary things that impact wave picking. If there are groups of order to be sent via the same delivery service, the WMS helps in the organization of those picking orders into waves so that they can meet pick up requirements and get fulfilled at similar times.

Delivery Zone

If customers are ordering similar types of products from geographic areas near one another, a geolocation specific wave can be set up. This helps in optimizing order fulfilment, pick up by the carrier, and shipping.

Determine What Picking Method is best

There are numerous picking strategies that a fulfilment centre can embrace. The wave process is best utilized by fulfilment centres operating during longer business hours or those with shipping flexibility.

Final Thoughts

Whether you have a warehouse for lease or using it on a personal basis, wave picking is an amazing way of utilizing resources correctly and avoiding bottlenecks. When it is implemented properly in a warehouse facility, operational costs can be significantly reduced which, in turn, boosts productivity and enhances the overall profitability to a greater extent.